As a processor you want to offer a quality product to your customers that reflects the highest standards in the industry while making sure you create the highest possible yield. Whatever your produce might be, tree nuts or groundnuts, the challenge remains to deliver the perfect product to your customers.

A piece of shell, glass or a stone? A rancid nut? Food safety regulations are being tightened worldwide and consumers have also become more demanding. The presence of foreign materials or inferior products is not only a matter of food safety - in times of growing competition, quality problems can be downright harmful to your reputation. Unfortunately, you cannot control the condition of the raw material, as no two seasons are the same. However, you do want to offer consistent quality to your customers.

In short, it’s important to optimize your sorting process: to detect as many foreign materials and defects as possible and without unnecessarily removing good products.

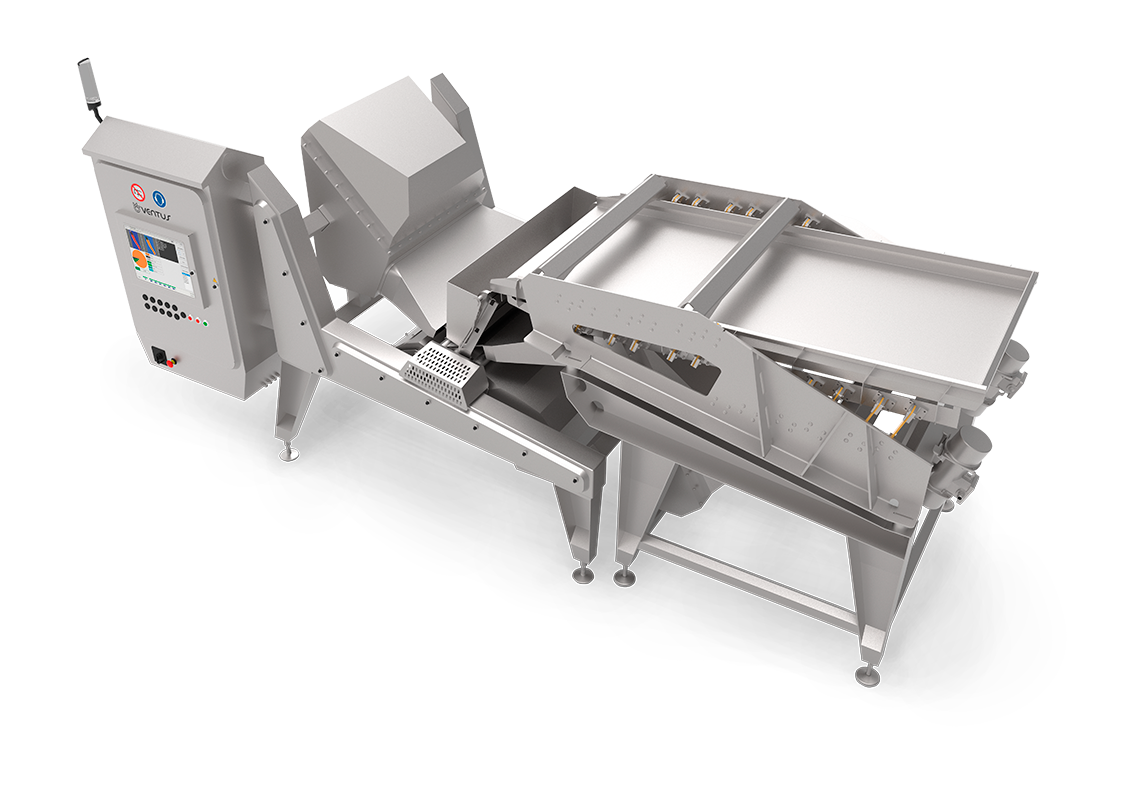

The VENTUS may be equipped with up to 16 lasers (and 32 laser detectors). With an impressive laser scanning speed of more than 4000 scans per second, it offers the highest resolution of all laser sorters on the market. In addition, all different laser signals are processed simultaneously by our Multi Dimensional Laser System (MDL) system, which outperforms all other systems.

In order to get an excellent good-to-bad ratio even for the smallest products, you can equip it with a high-resolution valve system: ultra-fast and small blowing jets with a center-to-center distance of 4.6 mm.

RADICALLY UPDATED

The Novus is available in different sizes. Its maximum scanning width of 2400 mm makes it the widest optical belt sorter on the market. The NOVUS may be used for many different applications: fresh, dried or frozen potato products, fruit and vegetables, crustaceans and shellfish, confectionery and nuts.

Most image processing algorithms reduce the RGBi signal of a colour camera from four to two dimensions. This may result in the loss of valuable information. All signals, both from the cameras and from the different lasers, are interpreted simultaneously by means of our algorithms, resulting in a more accurate detection of foreign objects and defects, plus a lower risk of false detections.

Accurate defect detection is pointless without an equally accurate ejection system. The distance between our air ducts, centre-to-centre is 7.5 mm instead of the usual 10 mm. Thus there are more ducts that are able to blow more effectively and that improves the ejection accuracy. There is also a high-resolution valve system with a centre-to-centre distance of 5 mm for specific applications. Optionally, also a double reject system is available resulting into a 3-way sort.

Why not use the data recorded by the cameras to adjust your sorting process where necessary? An optional module that filters data to parameters of your choice - length, shape, colour, defect level, etc. - and makes them available to your operators in a clear numerical or graphical way, so that they can intervene if desired. This module lays the basis for ‘sort to spec’.

Setting acceptance thresholds is often time-consuming and complex. This is not the case with Optimum Sorting systems. Your operators no longer have to work with graphs or formulae themselves. Our machines can easily be calibrated by selecting images of acceptable and unacceptable products.

Thanks to the CUMULUS sorting platform with Artificial Intelligence, operating our sorting machines is child's play. Your operators see all relevant information at a glance.

If you want to operate your sorting machines centrally, then no problem! Our solutions are easily integrated into your network, so that your operators and supervisors can keep an eye on things from any network computer.

Optimum Sorting systems are made from stainless steel and all components to be cleaned are easily accessible. This way hygiene is guaranteed and cleaning costs you hardly any time and effort.

Moreover our machines are designed in such a way that any contamination has no impact on the sorting. Furthermore, they excel in stability, which means that your sorting process requires virtually no manual intervention. You can switch from one product to another or from one specification to another with just one press of a button.

And finally, their sturdy construction offers you a maximum uptime with minimum maintenance.