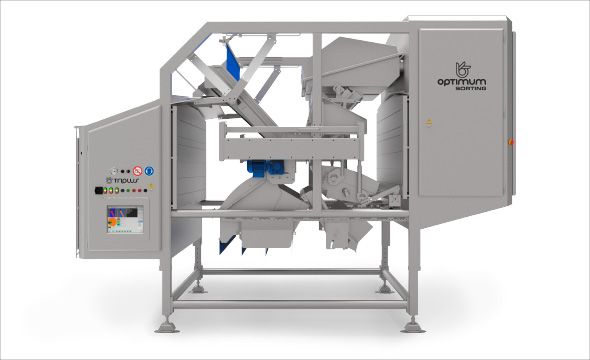

The TRIPLUS is an optical sorter especially developed to sort products with various optical deficiencies. Discoloration, deformation and foreign objects are detected and accurately removed from the product flow.

The TRIPLUS can be used for whole potatoes, vegetables, fruit as well as seafood. Use of the TRIPLUS will lead to quality improvement of your final product, but also to lower and more predictable production costs.

The double ejection unit enables us to split the product flow in three flows, for example:

- Accept product

- Product to be reprocessed

- Foreign bodies

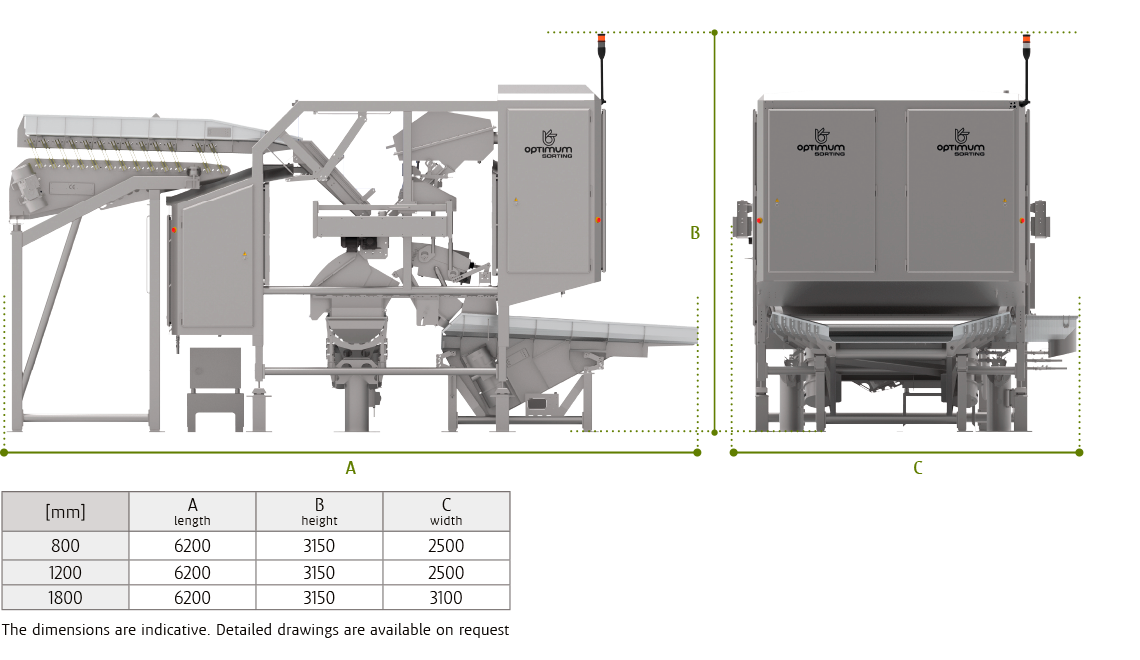

The TRIPLUS is available in three models with a scan width of 840, 1200 or 1800mm.

Standard

Standard Option

Option Not available

Not available