Beetles

For the OPTIMUM sorting of insects, we would like present the NOVUS.

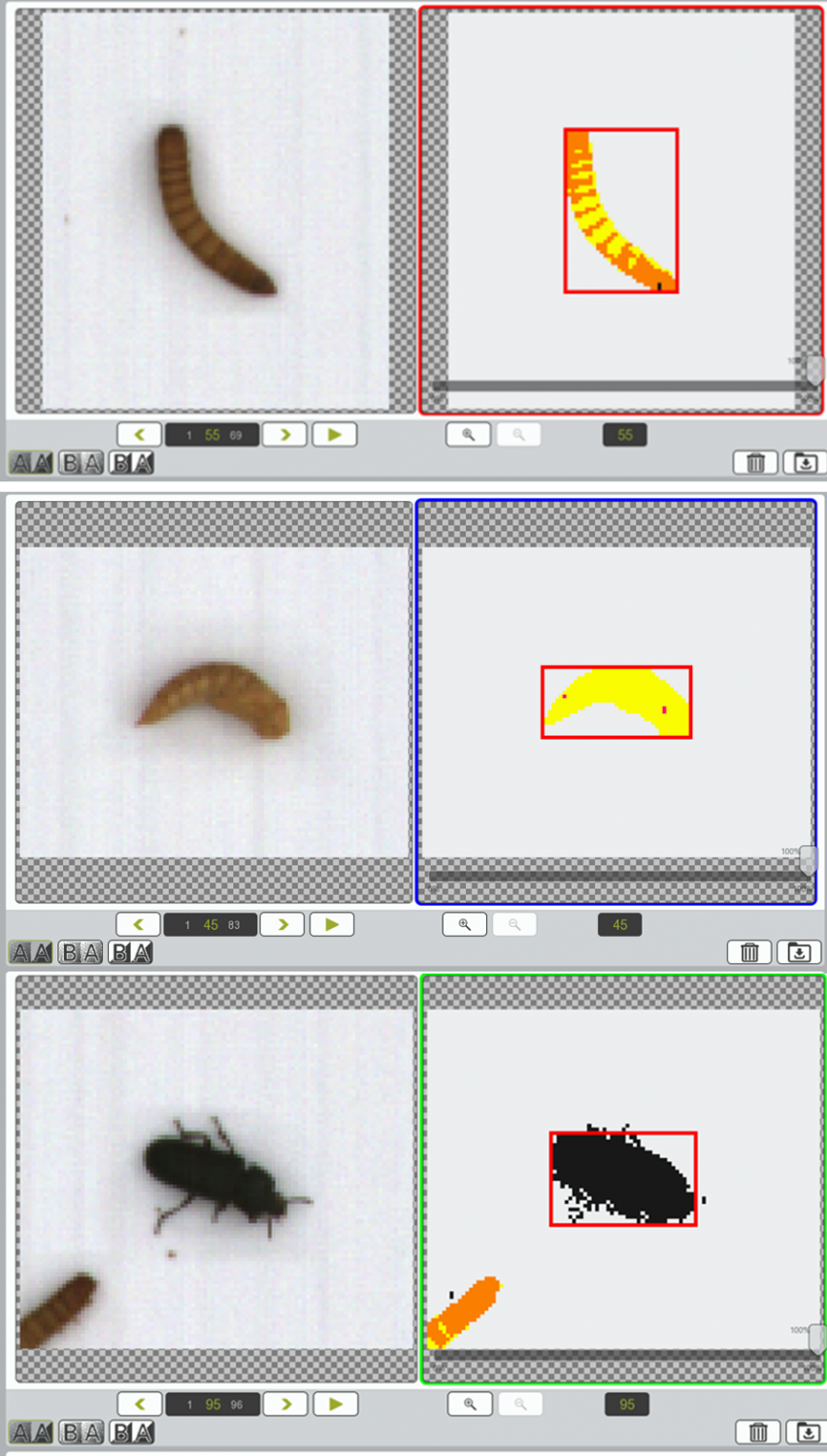

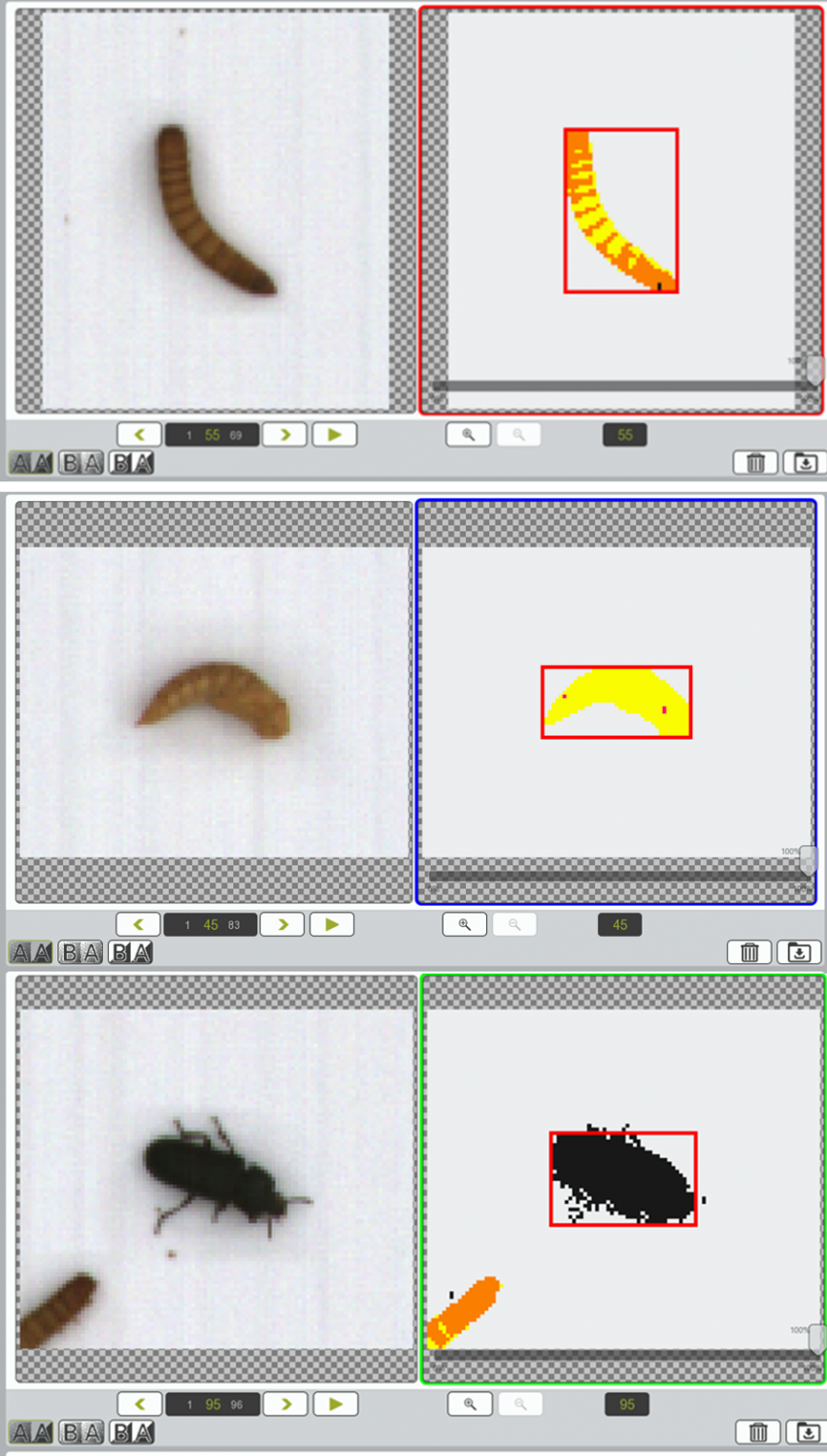

TYPICAL DEFECTS

- Separation of different life cycle stages (beetle vs mealworm vs pupae)

- Immature beetles

- Feed/skin remnants

For the OPTIMUM sorting of insects, we would like present the NOVUS.

TYPICAL DEFECTS

The Novus is available in different sizes. Its maximum scanning width of 2400 mm makes it the widest optical belt sorter on the market. The NOVUS may be used for many different applications: fresh, dried or frozen potato products, fruit and vegetables, crustaceans and shellfish, confectionery and nuts.

VDL Insect systems, business unit of the foodtech cluster of VDL Groep, contributes in making the feed and food sector more sustainable through the development of standard smart solutions and systems for insect production. Insect growers can be enabled to produce competitively against classic protein sources as they offer the technology and equipment to solve their production challenges. VDL brings biology, physics, high-tech knowledge and craftsmanship together in smart and reliable solutions. Based on their versatile and modular approach, they provide solutions for different production phases and factory capacity sizes. They also serve the industry with custom engineering and manufacturing.