Présentons notre nouveau membre de l'équipe !

Nous sommes très heureux d'accueillir Kurt Smets en tant que notre nouvel ingénieur qualité ! Depuis le 22 mai, Kurt veille à ce que nos machines soient de la plus haute qualité et que nos processus se déroulent encore plus facilement. Chez Optimum Sorting, tout tourne autour de la qualité supérieure. Avec Kurt à bord, nous sommes prêts à tenir notre promesse et à fournir des machines de tri encore meilleures !

Bienvenue à bord, Kurt ! Nous sommes ravis de t'avoir parmi nous !

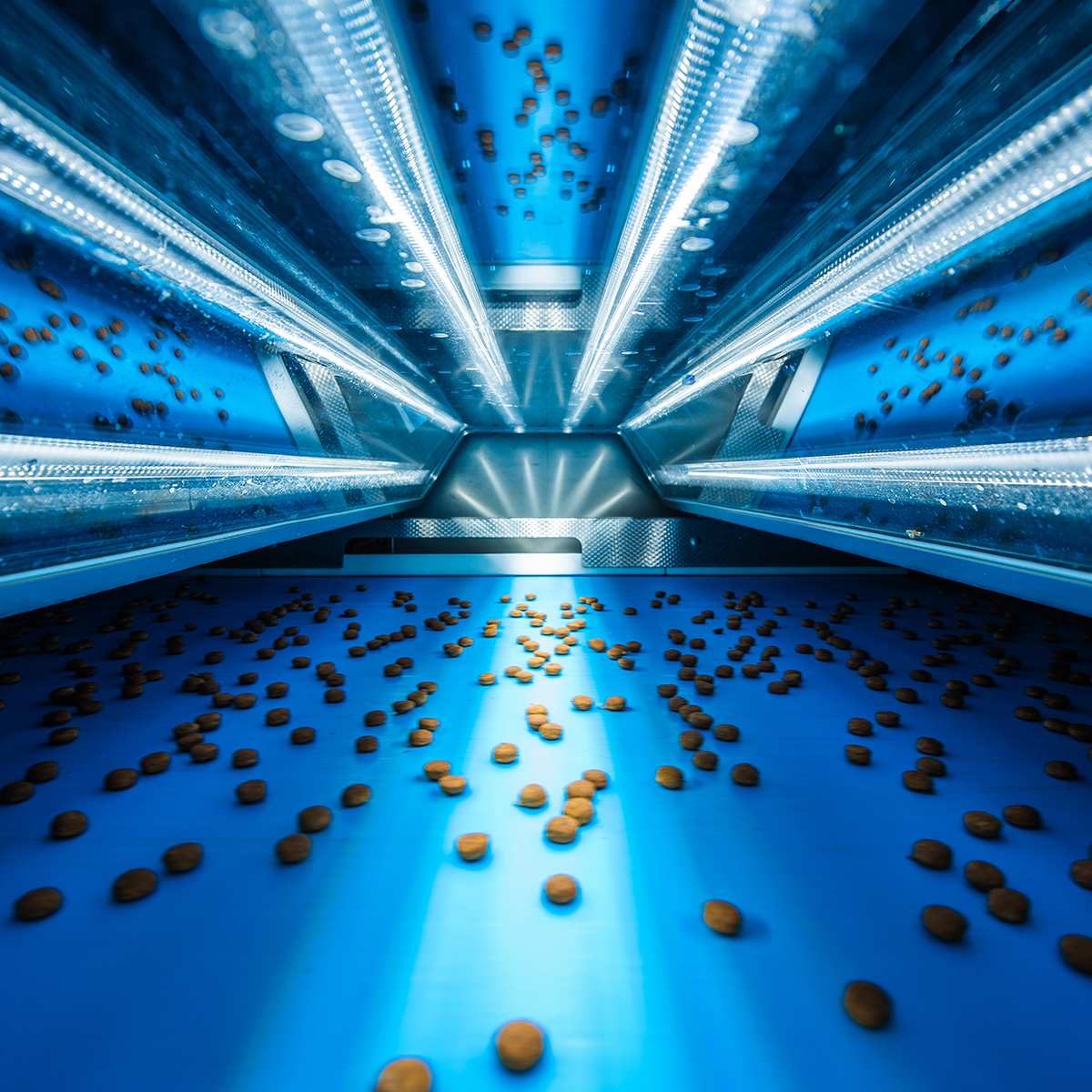

Trier le Meilleur pour Nos Amis à Fourrure !

Chez Optimum Sorting, nous sommes fiers de garantir que chaque bouchée de la nourriture de votre animal est parfaite ! Avec notre machine Novus, la nourriture pour animaux est triée avec une précision révolutionnaire, garantissant une qualité et une sécurité optimales pour vos compagnons à fourrure.

Choisir nos options de tri signifie bénéficier d'une multitude d'avantages :

- Assurance qualité des aliments

- Livraison de produits purs

- Moins de rejets faux positifs

- Détection de métaux disponible

- Excellent service mondial

Rejoignez-nous dans notre mission de fournir uniquement le meilleur pour nos compagnons à fourrure. Ensemble, nous gardons leurs queues frétillantes et leurs ronronnements forts !

Rencontrez notre nouveau génie du tri !

Dites bonjour à Gert Steegen, notre nouveau talentueux ingénieur logiciel qui se joint à nous dans notre quête d'innovation et d'excellence. Accueillons chaleureusement Gert alors qu'il apporte son expertise et sa passion à notre équipe dynamique !

Bienvenue à bord, Gert ! Nous sommes ravis de t'avoir parmi nous !

Présentons notre nouveau membre de l'équipe!

Accueillons Jim Vanderheyden, notre technicien en électricité talentueux qui nous rejoint dans notre parcours d'innovation et d'excellence! Jim apporte son expertise et son enthousiasme à notre équipe dynamique ici en Belgique.

Bienvenue à bord, Jim! Nous sommes ravis de t'avoir parmi nous!