Our machines

The Novus is available in different sizes. Its maximum scanning width of 2400 mm makes it the widest optical belt sorter on the market. The NOVUS may be used for many different applications: fresh, dried or frozen potato products, fruit and vegetables, crustaceans and shellfish, confectionery and nuts.

- widest optical belt sorter

- excellent good-to-bad ratio

- unique three-in-one combination of camera, laser and metal detection

- sorting on the basis of color, shape, structure and biological and magnetic properties

- superior resolution

- advanced sorting software using AI

- optimal flexibility and integration options

- perfect hygiene

- fast product switching

- 24/7 (remote) service

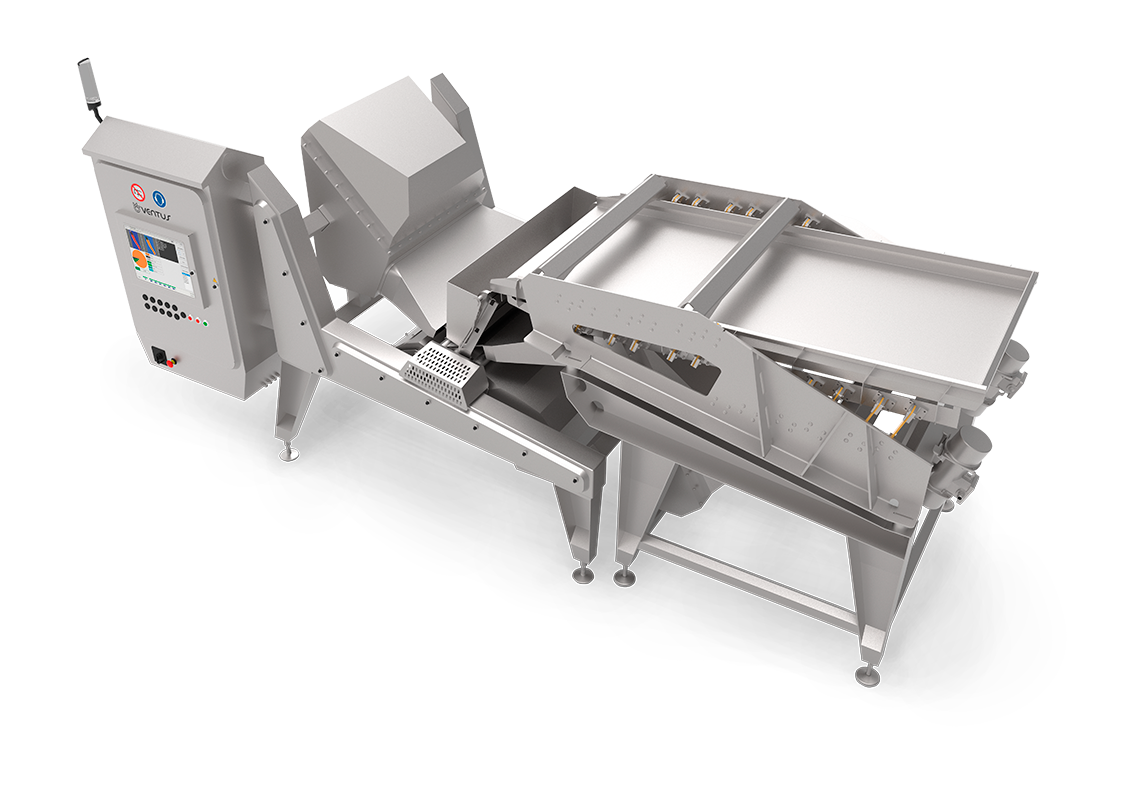

The VENTUS may be equipped with up to 16 lasers (and 32 laser detectors). With an impressive laser scanning speed of more than 4000 scans per second, it offers the highest resolution of all laser sorters on the market. In addition, all different laser signals are processed simultaneously by our Multi Dimensional Laser System (MDL) system, which outperforms all other systems.

In order to get an excellent good-to-bad ratio even for the smallest products, you can equip it with a high-resolution valve system: ultra-fast and small blowing jets with a center-to-center distance of 4.6 mm.

RADICALLY UPDATED

- widest double-sided free-fall laser sorter

- robust, advanced lasers

- excellent good-to-bad ratio

- sorting on the basis of color, shape, structure and biological characteristics

- superior resolution

- advanced sorting software using AI

- optimal flexibility and integration options

- perfect hygiene

- fast product switching

- 24/7 (remote) service